FEATURED PRODUCT

- The bed is made of high-strength cast steel intergrally welded structure, heavy weight to help the vibration stress relief.

- The bed is divided into compartments, each compartment has an auto opening and closing door to increase smoke extraction efficiency and energy saving.

- The Y-axis is installed in an inclined position to support the operation of devices smoothly, workpiece moves up and down more convinient, and the Y-axis is protected properly.

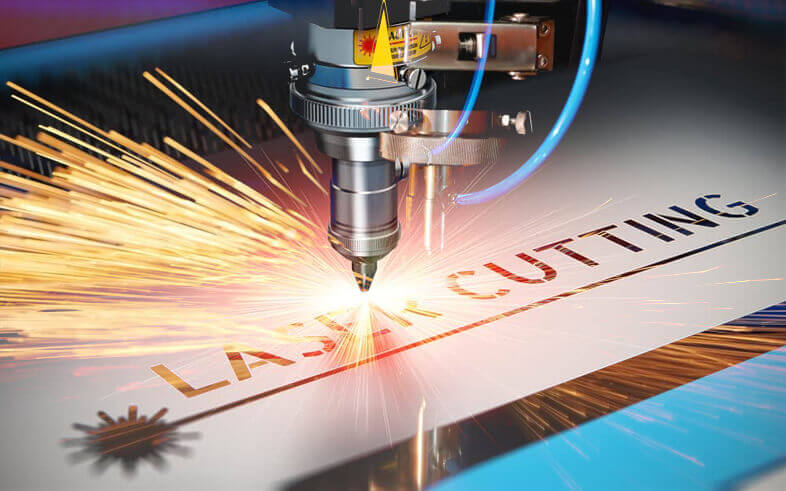

- The famous brands in the world of our FIBER LASER source including Trumpf, IPG, Raycus, Maxphotonics.

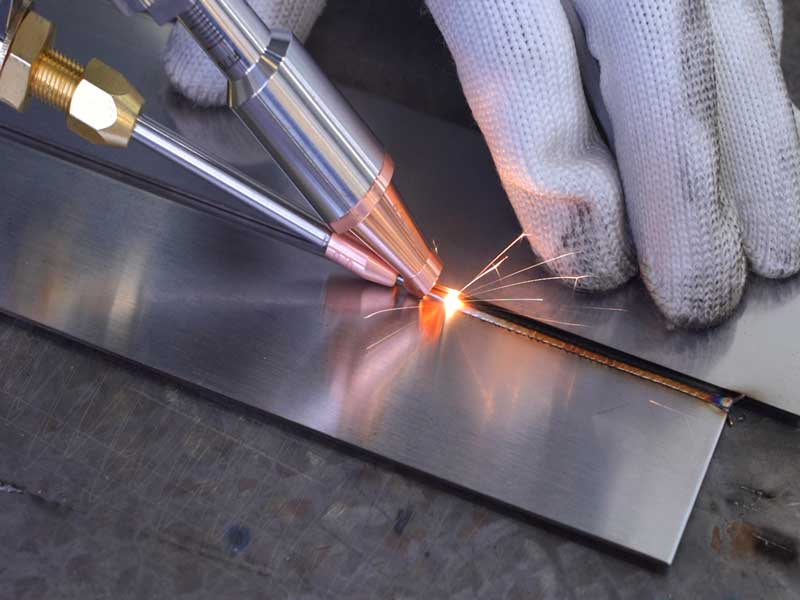

- The Raytools/Precitec Laser Cutting Head with auto sensor function is suitable for different focal lengths and controlled by the system.

- The servo system uses the Japanese Yaskawa AC servo motor and drive, which is a high accuracy as stable, reliable, good dynamic performance and strong load capacity.

- Auto Oxygen Pressure Regulator helps to control the flow and ensure the quality of cutting.

- Valves are designed to alert the pressure and airflow, detect failures of oxygen and nitrogen gas pressure.

- The axis X-beam is made by the special aluminum for laser cutting machines and light weight to assist the devices to move faster but still ensure to be good rigidity.

- Smart controller is specially designed for fiber laser cutting machine and especially, it’s user-friendly.

- The cutting parameters are stored depending on the material thickness. Selecting the available parameters in the library for using.

- The remote control is one of the many clever elements that make it easier to control the laser cutting machine.

- Auto lubrication system ensures the durability and it results in extended equipment life.

- Selecting the appropriate lubrication solution can help reduce premature bearing failures and increase machine uptime, productivity and energy efficiency.

TECHNICAL PARAMETERS

| PRODUCT MODEL | JLM3015 | JLM4015 | JLM4020 | JLM 6015 | JLM 6020 | JLM 6025 | |

| Max cutting size (mm) | 3000×1500 | 4000×1500 | 4000×2000 | 6000×1500 | 6000×2000 | 6000×2500 | |

| Effective travel | Axis X (mm) | 1530 | 1530 | 2030 | 1530 | 2030 | 2530 |

| Axis Y (mm) | 3050 | 4050 | 4050 | 6050 | 6050 | 6050 | |

| Axis Z (mm) | 170 | 170 | 170 | 170 | 170 | 170 | |

| Position Accurate | Axis X (mm) | ±0.03 | ±0.03 | ±0.03 | ±0.03 | ±0.03 | ±0.03 |

| Axis Y (mm) | ±0.03 | ±0.03 | ±0.03 | ±0.03 | ±0.03 | ±0.03 | |

| Axis Z (mm) | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | |

| Repeated Accurate | Axis X (mm) | ±0.02 | ±0.02 | ±0.02 | ±0.02 | ±0.02 | ±0.02 |

| Axis Y (mm) | ±0.02 | ±0.02 | ±0.02 | ±0.02 | ±0.02 | ±0.02 | |

| Axis Z (mm) | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 | |

| Rapid Positioning Speed | Axis X (m/min) | 90 | 90 | 90 | 90 | 90 | 90 |

| Axis Y (m/min) | 90 | 90 | 90 | 90 | 90 | 90 | |

| Axis Z (m/min) | 48 | 48 | 48 | 48 | 48 | 48 | |

| Fiber Laser Power (W) | 1000/1500/2000/3000/4000/6000 | ||||||

| Power Supply (V) | 380V/50Hz | ||||||

| Power Consumption (kWh) | 4.6~48 | ||||||

| Total Weight (Kg) | 4000 | 5000 | 6000 | 6500 | 8000 | 9000 | |

| Dimension (mm) | 4200x2200x1500 | 5200x2200x1500 | 5200x2700x1500 | 8200x2200x1500 | 8200x2800x1500 | 8200x3400x1500 | |

Leave a Reply