Featured Product

- The bed is made of high-strength cast steel intergrally welded structure, heavy weight to help the vibration stress relief. The bed is divided into compartments, each compartment has an auto opening and closing door to increase smoke extraction efficiency and energy saving.

- Exchange of table by lifting tools.

- The machine bed is fully covered to ensure the safety issues.

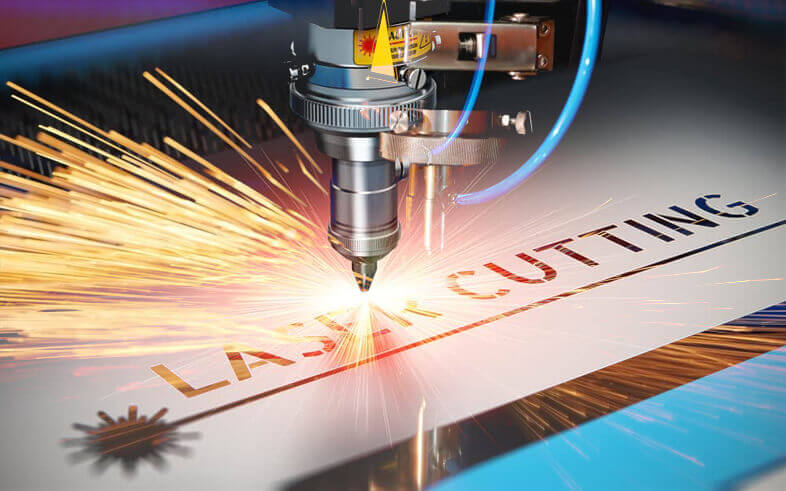

- The famous brands in the world of our FIBER LASER source including Trumpf, IPG, Raycus, Maxphotonics.

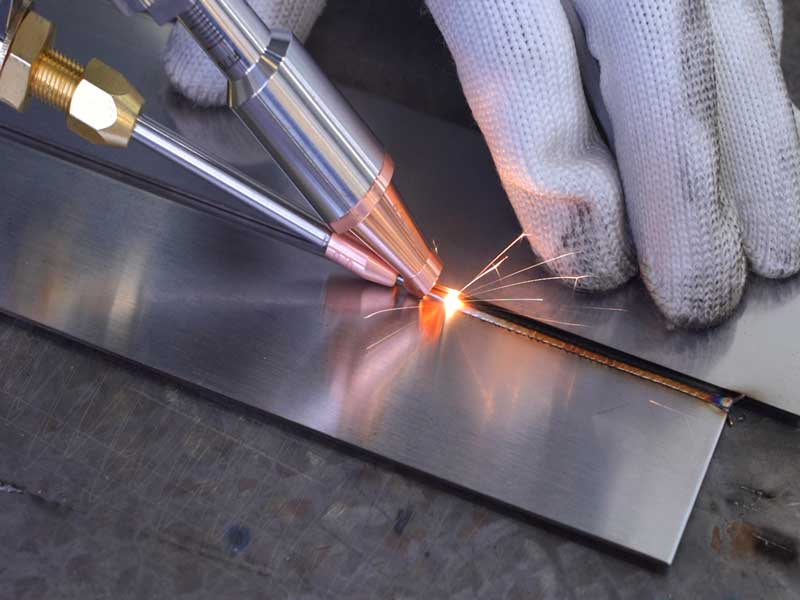

- The Raytools/Precitec Laser Cutting Head with auto sensor function is suitable for different focal lengths and controlled by the system.

- The servo system uses the Japanese Yaskawa AC servo motor and drive, which is a high accuracy as stable, reliable, good dynamic performance and strong load capacity.

- Auto Oxygen Pressure Regulator helps to control the flow and ensure the quality of cutting.

- Valves are designed to alert the pressure and airflow, detect failures of oxygen and nitrogen gas pressure.

- The axis X-beam is made by the special aluminum for laser cutting machines and light weight to assist the devices to move faster but still ensure to be good rigidity.

- Smart controller is specially designed for fiber laser cutting machine and especially, it’s user-friendly.

- The cutting parameters are stored depending on the material thickness. Selecting the available parameters in the library for using.

- The remote control is one of the many clever elements that make it easier to control the laser cutting machine.

- Auto lubrication system ensures the durability and it results in extended equipment life.

- Selecting the appropriate lubrication solution can help reduce premature bearing failures and increase machine uptime, productivity and energy efficiency.

- Low operational costs.

TECHNICAL PARAMETERS

| TÊN MÁY | JLMT3015 | JLMT4020 | JLMT6015 | JLMT6020 | JLMT6025 | JLMT12025 | |||

| Khu vực làm việc (mm) | 3000×1500 | 4000×2000 | 6000×1500 | 6000×2000 | 6000×2500 | 12000×2500 | |||

| Hành trình hiệu dụng của máy | Trục X (mm) | 1550 | 2050 | 1550 | 2050 | 2550 | 2550 | ||

| Trục Y (mm) | 3050 | 4050 | 6050 | 6050 | 6050 | 12050 | |||

| Trục Z (mm) | 100 | 100 | 100 | 100 | 100 | 100 | |||

| Định vị chính xác | Trục X (mm) | ±0.03 | ±0.03 | ±0.03 | ±0.03 | ±0.03 | ±0.03 | ||

| Trục Y (mm) | ±0.03 | ±0.03 | ±0.03 | ±0.03 | ±0.03 | ±0.03 | |||

| Trục Z (mm) | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | |||

| Định vị lại chính xác Repeated Accurate | Trục X (mm) | ±0.02 | ±0.02 | ±0.02 | ±0.02 | ±0.02 | ±0.02 | ||

| Trục Y (mm) | ±0.02 | ±0.02 | ±0.02 | ±0.02 | ±0.02 | ±0.02 | |||

| Trục Z (mm) | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 | |||

| Tốc độ di chuyển không tải tối đa | Trục X (m/min) | 240 | 240 | 240 | 240 | 240 | 240 | ||

| Trục Y (m/min) | 240 | 240 | 240 | 240 | 240 | 240 | |||

| Trục Z (m/min) | 48 | 48 | 48 | 48 | 48 | 48 | |||

| Công suất nguồn Laser (W) | 1000/1500/2000/3000/4000/6000/8000/10000/12000/15000/20000/30000/40000 | ||||||||

| Nguồn điện cung cấp (V) | 380V/50Hz | ||||||||

| Công suất tiêu thụ (kWh) | 4.6~90 | ||||||||

| Tổng trọng lượng máy (Kg) | 10500 | 16000 | 17000 | 20000 | 22000 | 45000 | |||

| Kích thước tổng thể của máy DxRxC (mm) | 8600x2800x2100 | 10500x3600x2100 | 15000x2800x2100 | 15000x3500x2100 | 15000x4000x2100 | 27000x4000x21000 | |||

Leave a Reply